Top Categories

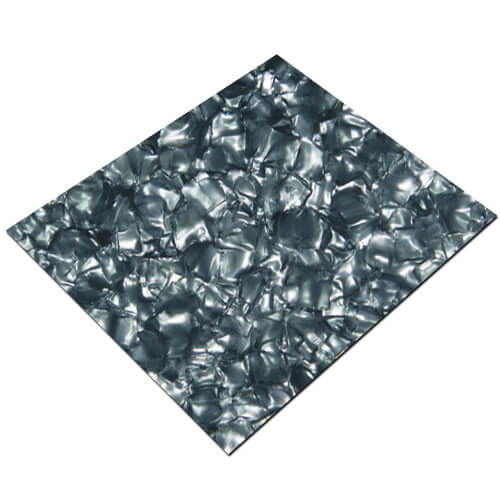

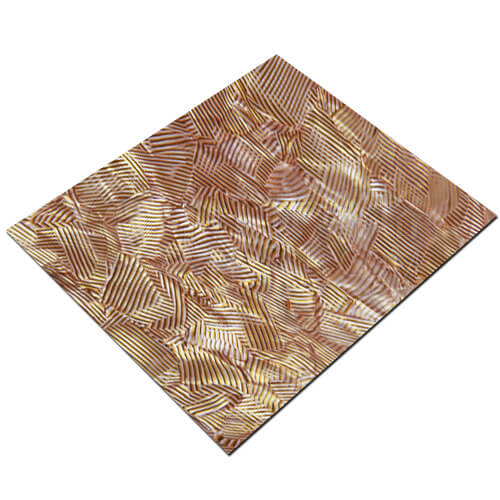

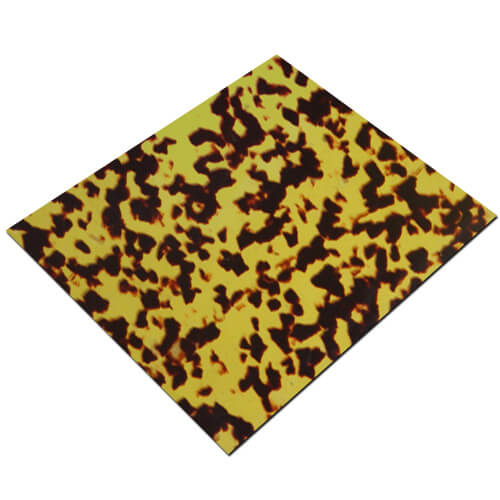

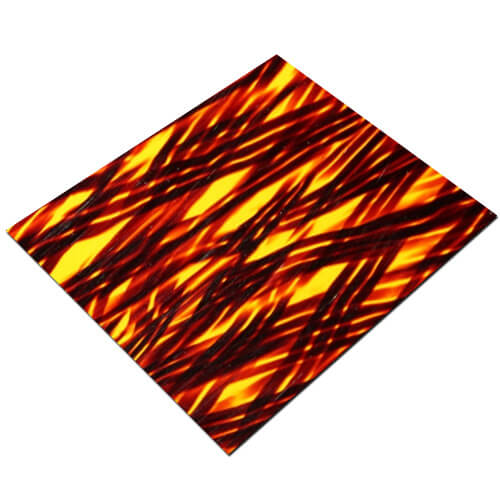

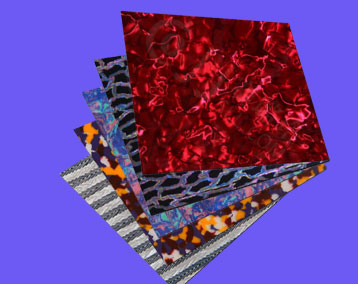

Pattern Celluloid Sheet Series

Military Celluloid Sheet Series

Ecoloid Celluloid Sheet Manufacturer

Ecoloid Celluloid Co., Ltd. specializes in the production of a wide range of military materials, including celluloid sheets, agate film, ice flower film, jewelry headwear, pearls, eyewear, musical instruments, picks, coatings, and inks.

With first-class development and design expertise and experienced technical personnel, we utilize advanced machinery and imported production technology. Our products offer exceptional quality, vibrant colors, high gloss, durability, and a comprehensive range of designs and colors. We rigorously test and inspect our products, and can customize them to meet specific customer needs…Learn More

Hot Topic News & Articles

Ecoloid Celluloid Sheet

if you are interested with celluloid material,please send email to us

Frequently Asked Questions

Our factory prioritizes environmentally friendly production and has obtained ISO 14001 environmental management system certification. Our environmental management measures during production are as follows:

Waste Gas Treatment: Trace volatile gases generated during the nitrocellulose processing process are purified by a dual treatment system combining activated carbon adsorption and UV photolysis before discharge. Emission concentrations comply with the “Integrated Emission Standard for Air Pollutants” (GB 16297-1996).

Wastewater Treatment: Wastewater from equipment washes is treated at the factory’s sewage treatment station (using a “coagulation and sedimentation + biochemical treatment” process) to meet the Class III standard of the “Integrated Emission Standard for Wastewater” (GB 8978-1996). It is then sent to a municipal sewage treatment plant for advanced treatment.

Solid Waste Treatment: Production scraps (celluloid waste) are flammable solid waste and are professionally incinerated or recycled by qualified hazardous materials disposal companies. They are not discarded carelessly. Annual environmental inspection reports issued by the environmental protection department are available.

Payment Methods: Flexible cooperation models are available. New customers can choose a “30% down payment + 70% final payment” arrangement.

After-sales Service:

If customers discover that the product does not match the order, the packaging is damaged, or there are quality issues (such as substandard ingredients or impurities) after delivery, they must provide photo/video evidence within 7 days of arrival. Our factory will respond within 24 hours and offer free reissue, return and refund, or discount.

If customers encounter processing or storage difficulties during use, they can contact our technical team at any time (we provide a 24-hour technical consultation hotline) to assist in resolving issues such as mold cracking and color unevenness.

Free samples are available.

Sample Range: Standard sheet materials are available free of charge (sample quantity per specification cannot exceed 1kg). Customized samples (e.g., special colors or sizes) require a small sample fee, which can be fully deducted from the purchase price after ordering.

Shipping Time: Standard samples can be shipped the same day. Customized samples take 5-7 business days to produce. We ship by air.

Our factory currently has an annual celluloid production capacity of 1,000 tons, which can meet the regular purchasing needs of small and medium-sized enterprises. For customers with long-term cooperation plans involving 10,000 tons, we can discuss capacity expansion plans three months in advance.

Regular orders (50-200 kg): Stock specifications (such as standard thickness sheets and standard color granules) are shipped within 72 hours, while custom specifications (special sizes and exclusive colors) are delivered within 5-7 business days.

Bulk orders (over 500 kg): These orders are subject to production schedules and are generally completed within 10-15 business days.

Stable supply guarantee: We have long-term supply agreements with three Tier 1 suppliers for raw materials (nitrocellulose and camphor). We maintain inventory sufficient to support three months of production. We have also established an early warning mechanism for raw material price fluctuations. If prices increase, we will communicate price adjustments to customers 15 days in advance to ensure stable cooperation.

The core performance parameters of celluloid are as follows, and their suitability can be tailored to the specific industry scenario:

Heat resistance: The upper limit for short-term temperature resistance is 60-80°C (it softens and deforms easily above 100°C, so avoid high-temperature environments).

Abrasion resistance: The surface hardness is moderate (Rockwell hardness approximately R60-R70), making it suitable for applications without severe friction (such as handicrafts and decorative pieces). For applications requiring high-frequency friction (such as small mechanical parts), we can provide a wear-resistant coating.

Aging resistance: Prolonged exposure to strong light (especially UV rays) can easily fade and become brittle, making it more suitable for indoor use (such as vintage stationery and display crafts). For short-term outdoor use, we can recommend a suitable anti-aging agent.

Before collaborating, we will first understand your specific application scenario (such as exposure to high temperatures, outdoor use, and any friction requirements) and provide free samples for testing to ensure that the product’s performance meets your requirements.

product type :Celluloid sheets,Celluloid film and celluloid tubes

product specification :Thickness 0.17-5.0 mm ,length 1300×700MM ,1400×700MM ,1500×700MM, 1500×750MM, 1500×900MM ,1580×620MM, 1600×700MM ,1700×750MM, 2000×900MM, 2400×1200MM

Customization service: including sheets/tubes of specific thickness/size, exclusive color matching (color card numbers provided), and adjustment of material flexibility (achieved by optimizing the camphor addition ratio). We can also provide primary processing services such as pre-cutting and pre-carving (simple shapes) based on customer product requirements. The minimum custom order quantity can be as low as 50kg (depending on the difficulty of customization).

Yes, celluloid is classified as a Class 4.1 flammable solid and its transportation and storage must comply with hazardous materials regulations.

Transportation Solutions: Our factory has long-term partnerships with qualified logistics companies and offers dedicated road and rail transport services for hazardous materials. Our transport vehicles are equipped with fire protection devices, temperature monitoring equipment, and emergency fire extinguishing equipment. A “Dangerous Goods Transport Appraisal” and a “Material Safety Data Sheet (MSDS)” will be included with the shipment to ensure compliance with the Ministry of Transport’s “Dangerous Goods Road Transport Regulations.”

Storage Guidance: We provide customers with a “Celluloid Storage Safety Manual,” detailing storage temperature (15-25°C), humidity (40%-60%), fire separation distances, and isolation requirements (away from open flames, oxidizers, and heat sources).

Procedure Assistance: If customers wish to arrange their own transportation, our factory can assist with obtaining the necessary test reports and certification documents for obtaining a hazardous materials transport permit, ensuring a smooth transition to the transportation process.

The celluloid we produce strictly adheres to Q/331123 ZL 001-2019, 《Safety Technical Requirements for Celluloid Products》 (the current national standard), as well as the internationally recognized standards ASTM D1414 (American Society for Testing and Materials) and EN 71-2 (EU standard for the safe combustion performance of toys, targeting downstream products involving celluloid).

We have obtained a production safety license, a hazardous chemical business license (due to the flammability of celluloid, special qualifications are required), and ISO 9001 quality management system certification. Each batch of product is accompanied by a third-party test report (covering indicators such as combustion performance, component content, and hazardous substance limits). Upon request, we can provide a copy or electronic version of the full set of qualification documents.